The graphite electrode is made of high-quality petroleum coke, needle coke, coal pitch and other raw materials through calcination, intermediate crushing, screening, dosing, mixing, compression, roasting, high pressure impregnation, graphitization, machining and other processes, has compact and even structure, good electric conduction and heat-conducting properties, high mechanical strength and strong oxidization corrosion resistance at high temperature, is widely used for arc furnaces and submerged arc furnaces to smelt various alloy steel, yellow phosphorus, industry silicon, brown aluminum oxide and other alloy and nonmetal materials and is an important component of modern raw material industry.

Packaging Instruction: The packing case is a framework welded by angle iron and band steel and has solid wood laths inside to protect electrodes, the end parts of the packing case use wooden plywood to protect electrode socket and nipples, the bottom of the case uses square timber as skid, the inside uses plastic wrap to prevent moisture and dust and the outside is tied up by 6-8 steel belts. It is beautiful and firm and suitable to be transported by railway and by sea.

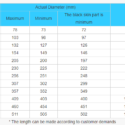

1. Please refer to electrode current capacity when steel-making electrode selects electrode diameter.

2. Avoid rain and snow when the graphite electrode is transported and stored and need to be dry before use.

3. Handle with care, protect thread and prevent clash and breakage when the graphite electrode is loaded, unloaded and transported.

4. Before connecting electrodes, use compressed air to blow off electrode thread and tighten nipple and electrode.

5. The electrode regulator system shouldn't sway during operation, so as to prevent loosing and tripping of nipple.

6. The electrode holder cannot near nipple and socket to hold the electrode.

7. When charging into the furnace, large steel blocks should be put on the lower part to prevent fallen materials break electrode in melting.