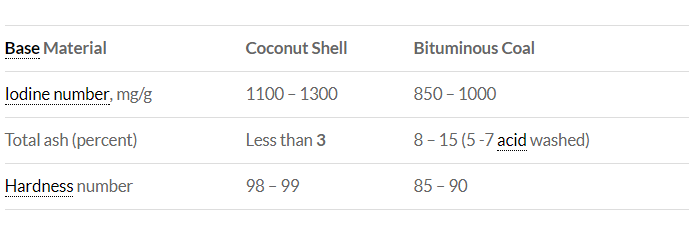

Coconut shell based activated carbons has Lower Ash Content, Higher Amount of Micropores, Higher Iodine Number, Excellent Hardness and it is very efficient in the removal of small size organic impurities.

Activated carbon from coconut shell has predominantly pores in micro pore range. Almost 85-90% surface area of coconut shell activated carbon exists as micro-pores. These small pores match the size of contaminant molecules in drinking water and therefore are very effective in trapping them.

Macro-pores are considered as an access point to micro-pores. Meso-pores do not usually play an important role in the adsorption unless the surface area of these pores is large, 400 m2/g or more. The predominance of micro-pores in coconut shell carbon gives it tight structure and provides good mechanical strength and hardness and also high resistance to resist attrition or wearing away by friction.

Coconut shell-based AC has the most micropores. Micropores are defined as pores less than 20-angstrom units (two nm) in diameter. Coconut shell based carbons are excellent for Point of Use (POU) and Point of Entry (POE) applications because of lower ash content and excellent microporus structure.

The very large internal surface areas characterized by microporosity along with high hardness and low dust make these coconut shell carbons particularly attractive for water and critical air applications as well as point-of-use water filters and respirators.

Coconut Activated Carbon Hardness Number is around 98 but Bituminous Coal Activated carbons hardness number is only 85 – 90.

Some of other features which carbon industries, see as a great advantage in favour of coconut carbon are as follows:

- Coconut is a renewable source of carbon

- Coconuts grow throughout the year, with harvesting generally occurring 3-4 times in a year

- Coconut tree can be preserved for many years