A three-dimensional honeycomb of hexagonally arranged carbon has been termed 3D graphene.

3D graphene, also known as a graphene aerogel or a three-dimensional graphene nanostructure, is characterized by its porous and three-dimensional framework. Graphene, in its essence, consists of a single layer of carbon atoms arranged in a hexagonal pattern. In contrast, when multiple layers of graphene are stacked, it forms graphite, a common material used as the “lead” in pencils. However, graphite’s mechanical properties are relatively weak due to the close stacking of graphene sheets. To address this limitation, a porous variation of graphene, namely graphene aerogel, can be produced by introducing air-filled pores between the graphene sheets. This unique structure allows the three-dimensional graphene to maintain the exceptional properties of graphene while enhancing its mechanical robustness.

3D graphene, often referred to as 3D graphene foam or graphene aerogel, is a three-dimensional structure composed of graphene, a single layer of carbon atoms arranged in a hexagonal lattice. While traditional graphene is a two-dimensional material, 3D graphene extends into the third dimension, forming a porous and lightweight structure.

The creation of 3D graphene typically involves the following steps:

- Graphene Oxide Production: Graphene oxide is derived from graphite, and it contains oxygen-functional groups, making it easier to disperse in solvents.

- Reduction: The graphene oxide is reduced, removing some of the oxygen functional groups to restore the electrical conductivity of the material.

- Self-Assembly: The reduced graphene oxide sheets self-assemble into a three-dimensional network through various methods, such as freeze-drying or chemical reduction.

The resulting 3D graphene structure has several notable properties and applications:

- Lightweight and Porous: 3D graphene is extremely lightweight and porous, making it an ideal material for applications where weight reduction is crucial, such as aerospace and materials for batteries and supercapacitors.

- High Surface Area: Its large surface area allows for enhanced adsorption and catalytic activity, making it valuable in applications like environmental remediation, water purification, and gas adsorption.

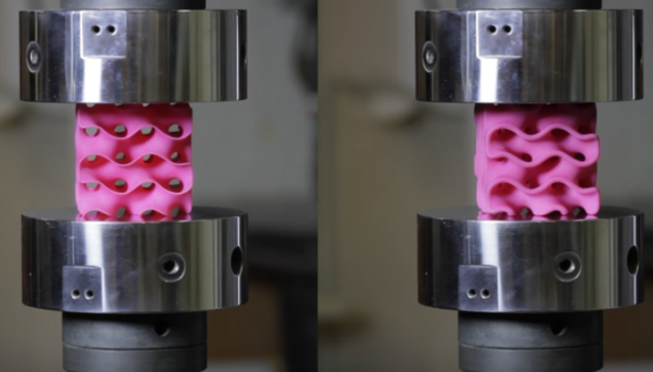

- Mechanical Strength: 3D graphene exhibits good mechanical strength, which is useful for structural applications and can be incorporated into composites.

- Thermal and Electrical Conductivity: It maintains excellent thermal and electrical conductivity, making it useful in applications like heat sinks and electronic devices.

- Energy Storage: 3D graphene can be used to create high-performance energy storage devices like supercapacitors and batteries, due to its excellent electrical conductivity and large surface area.

- Sensors: It can be used to create highly sensitive sensors for various gases and molecules.

- Catalyst Support: 3D graphene can serve as a support for catalyst materials, improving their performance in chemical reactions.

3D graphene’s unique properties make it a promising material for a wide range of applications, and ongoing research continues to explore its potential in various fields, including materials science, electronics, energy storage, and environmental engineering.